- Newsroom

SenseTime Recognized as a Top 50 Best Practice Company in China’s Digital Economy

AI-enabled Automatic Hazard Detection in High-Speed Railways to Ensure Passenger Safety

January 14, 2022 – SenseTime has been recognized as one of the top 50 service providers implementing best practices in China's booming digital economy, according to the China Digital Economy Industry Best Practices 50 report from the APEC China Business Council (ACBC).

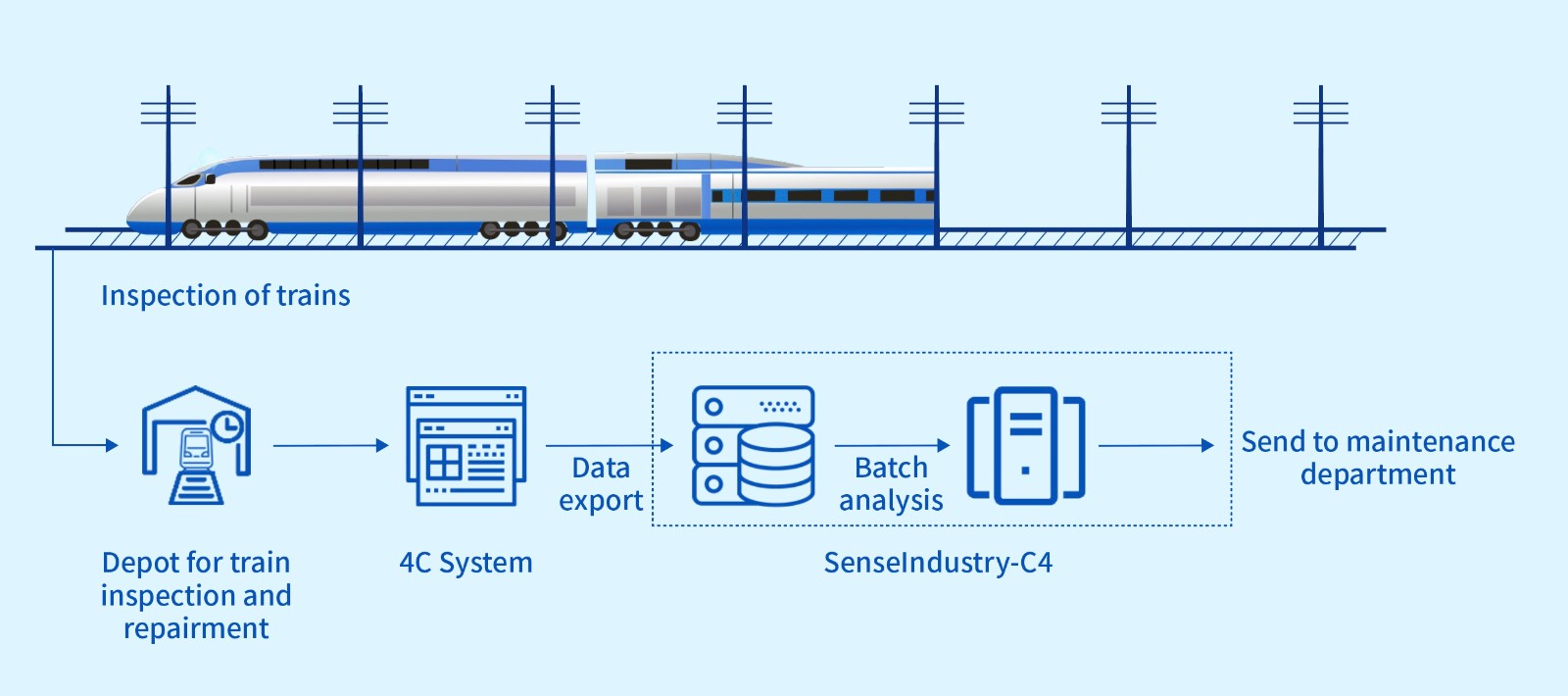

Backed by its proprietary SenseCore AI infrastructure, SenseTime’s 4C[1] intelligent analysis system SenseIndustry-C4 (“System”) automatically detects catenary defects in high-speed railways, enhancing the safety of every passenger in the journey. The application has been selected as one of the best examples of accelerating digital transformation of traditional industries through AI.

Launched by the ACBC, the influential China Digital Economy Industry Best Practices 50 report is the culmination of a joint effort by top research institutes, think-tanks and consulting firms, providing comprehensive and critical insights into how the application of digital technologies are reshaping different industries in the world's second-largest economy. The selection followed rigorous procedures including application screening, expert on-site reviews, assessment meetings and follow-up reviews.

Improved Efficiency of Catenary Defect Detection by 20 Times

High-speed railway inspection has traditionally relied on maintenance workers to conduct manual track inspections for potential hazards overnight. It can take up to 3 years to complete a comprehensive manual inspection, meaning new safety hazards may appear before the end of an inspection cycle.

Although 4C catenary inspection technology is being applied to high-speed rail inspections and the detection time is shortened to a quarter of the original time by taking photos instead of manual detection, the analysis of each photo still needs to be done manually.

Since 2017, SenseTime has cooperated with the operator of the Beijing-Shanghai high-speed railway to together explore the application of AI in catenary defect detection. The inspection of this 1,318-km high-speed railway line captures 3 million photos of railway components every quarter, 8,000 of which must be analysed manually every day. Previously, more than 20 technicians needed to work overtime for 20 days to conduct this analysis.

However, following the introduction of SenseIndustry-C4, the analysis of 3 million photos can be completed within 10 days and by just two technicians, improving the efficiency by more than 20 times and reduces the chance for human error. This allows other technicians to be redeployed to other areas to further improve the system and overall passenger experience.

AI Industrial Engine to Address Traditional Industry Challenges

SenseTime unveiled the AI Industrial Engine based on its universal AI infrastructure SenseCore last year to enable rapid and mass development of specific AI models and algorithms, including defect detection for industrial sectors.

The SenseIndustry-C4 is one of the best examples to showcase the potential of the AI Industrial Engine. The System can automatically identify defects of various railway components. For example, the detection rate of dropper’s breakage increased from 73% to 95.7%, which significantly improved the efficiency and convenience of manual inspection.

Up to now, the national high-speed railway analysed by the system has exceeded 30,000 kilometres, with over 48 million photos analysed, including more than 1.3 billion railway components.

By upholding its mission to create a better AI-empowered future through innovation, SenseTime will continue to provide strong support for the rapid development of the railway industry and promote AI empowerment in all walks of life.

[1] High-precision Catenary-Checking Monitor Device

You haven't completed the information

After completing the information,

you can download the information

Return

Return Smart Business

Smart Business Smart City

Smart City Smart Life

Smart Life Smart Auto

Smart Auto